Star Cool 1.1 – Meeting International Safety Standards with climate friendly refrigerant R1234yf

Maersk Container Industry (MCI) has introduced a third refrigerant option for the new reefer unit model, Star Cool 1.1. This new option, R1234yf, is compliant with global refrigerant regulations and significantly reduces the carbon footprint of the reefer, aligning with the shipping industry’s net zero ambitions.

R1234yf is classified as A2L, meaning it is mildly flammable, which is a notable change from the currently used non-flammable A1 refrigerants like R134a. To ensure safety with this new refrigerant, MCI made design modifications to comply with ISO 20854, the safety standard for thermal containers using flammable refrigerants.

The ISO 20854 standard, released in October 2019, was developed by a working group that included representatives from refrigerating system manufacturers, refrigerated container box manufacturers, shipping lines, classification societies, equipment owners, and other industry experts. This standard mandates the conduction of an Operational Mode Risk Assessment (OMRA).

The OMRA methodology assesses risks in various operational modes, considering hazards from the ignition of the flammable refrigerant and potential toxicity threats from igniting a fluorinated gas like R1234yf. All fluorinated gases, including R134a and R513A, can decompose into toxic substances under certain conditions, such as fire or excessive heat.

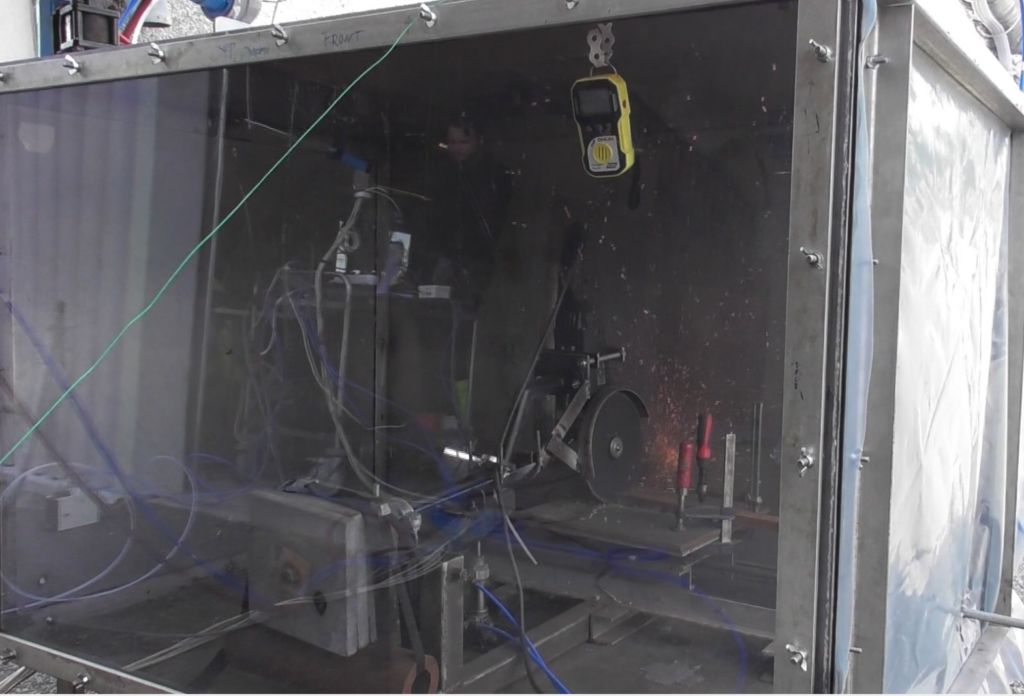

Apart from small scale testing, risks from the operational mode risk assessment were evaluated by test to review the assumptions made. Here a case of a technician cutting into a refrigerant charged system with a torch was investigated.

To address these challenges, MCI collaborated with the Advisory Team from DNV to quantify the risk parameters ‘probability’ and ‘severity’ for identified hazardous scenarios.

__________________________________________

“This has been an excellent cooperation, and our team has been impressed with MCI’s, careful and conservative approach to addressing the risks associated with using R1234yf in the Star Cool 1.1 unit. By focusing on detailed risk assessment and incorporating thorough real-world testing, MCI demonstrated that meeting the safety and compliance standards in ISO 20854 was a priority. We need to pull every lever in advancing the sustainability of our industry, and we are proud to work with customers who are committed to building trust in new solutions through rigorous independent testing.”

– Stephan Eylmann, Principal Engineer, Safety & Systems Engineering in DNV Maritime Advisory

__________________________________________

This assessment drew on several knowledge sources, including MCI’s extensive operating experience with reefer containers, publications from the German Federal Institute for Materials Research and Testing (BAM), material property and safety information from the refrigerant maker, and numeric simulations for toxic cloud size and concentrations.

The acceptance criteria for the risk assessment were derived from ISO 20854 requirements. The OMRA was conducted conservatively, which may have led to some scenarios being assessed as unacceptably high risk. MCI then devised and conducted a test programme to evaluate whether these scenarios represented the suggested dangers in real world conditions.

The evaluation program included a series of tests along with two dispersion simulations. After conducting these tests, the results were reviewed and compared against the OMRA assumptions. The final conclusions showed that these scenarios, when reassessed with the inclusion of the test and simulation results, met the criterion of being one order of magnitude below the tolerance line specified in the ISO 20854 risk matrix.

In a small scale test set-up, various tools were investigated for their potential to be an ignitions source. In this example and hand grinder, cutting into a steel plate, is placed in a flammable atmosphere of R1234yf. No ignition was observed throughout the flammability range.

The image shows a door opening scenario investigating the severity of releasing a full charge of 4.5 kg R1234yf, contained inside of the reefer. The outflowing refrigerant air mixture is led to a ignition source (here: Trough filled with Ethanol and ignited) and nurturing the existing flames slightly. This example showcases the poor flammability of R1234yf and the acceptable risk from operation.