Surface treatment

A new era in container durability

We are proud to introduce our superior surface treatment process, a groundbreaking advancement in container longevity and durability. Central to this innovation is our automated zinc metallizing treatment, a technique that has set new standards in the industry for corrosion protection.

Zinc metallizing: The core of superior protection

Zinc metallizing, a process used for over 50 years across various industries, is an integral part of MCI’s surface protection strategy for our containers. This method involves the application of a zinc layer on the container’s surface, which acts as a powerful shield against corrosion. The benefits of zinc metallizing include:

- Enhanced corrosion resistance: The zinc layer provides exceptional protection against rust and corrosion, significantly extending the container’s lifespan.

- Environmental sustainability: The process emits no volatile organic compounds (VOCs), involves no chemical waste, and ensures no water contamination, aligning with our commitment to environmental stewardship.

- Energy efficiency: Zinc metallizing consumes less energy compared to traditional methods, reducing our carbon footprint.

Comprehensive surface treatment process

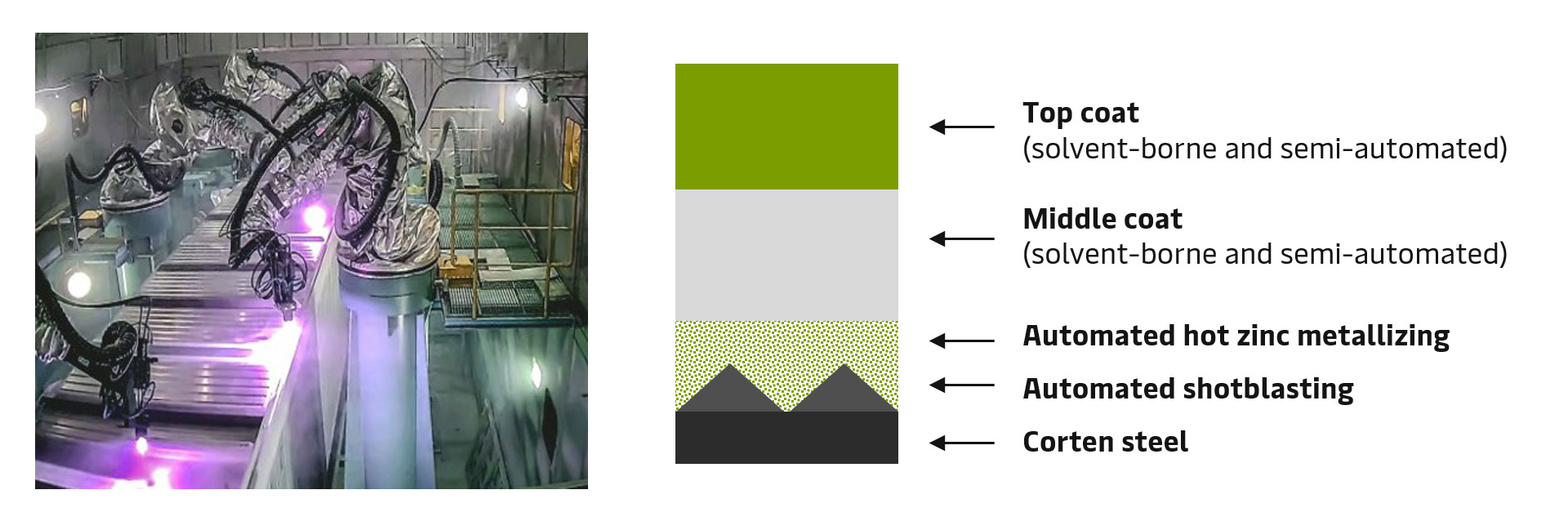

Robotized shotblasting

Our treatment process begins with robotized shotblasting, where corten surfaces are meticulously cleaned to create the perfect canvas for further treatments. This process ensures 100% efficiency in surface preparation, setting the stage for optimal coating adherence.

Automated hot zinc metallizing

Following shotblasting, automated hot zinc metallizing is applied. This step is crucial for achieving the unparalleled corrosion resistance that MCI containers are known for. The zinc layer is applied evenly by advanced robotic technology, ensuring consistency and quality.

Advanced coating system

Our containers then receive a middle coat and top coat, both solvent-borne and semi-automated, providing additional layers of protection and enhancing the container’s aesthetic appeal. This multi-layered approach ensures first-class surface protection against various environmental factors.

Quality and safety: Our top priorities

Quality control is paramount in our surface treatment process. We adhere to stringent ISO standards for measuring dry film thickness, ensuring that each container meets our high-quality benchmarks. Moreover, the automation of our treatment line not only enhances quality consistency but also significantly improves employee safety by reducing exposure to hazardous environments.

Get in touch